Failure Analysis – Cracked Pressure Swing Absorber (PSA) Vessels

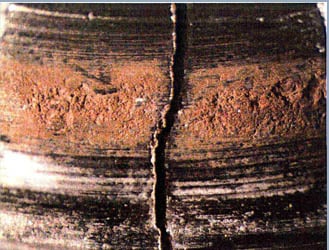

Failure analysis and repair of Pressure Swing Absorber (PSA) Vessels – in service at a hydrogen plant – found to exhibit chevron cracks

Failure Analysis – Cracked Pressure Swing Absorber (PSA) Vessels Read More »