Weld Solutions to Keep You Compliant to Engineering Codes

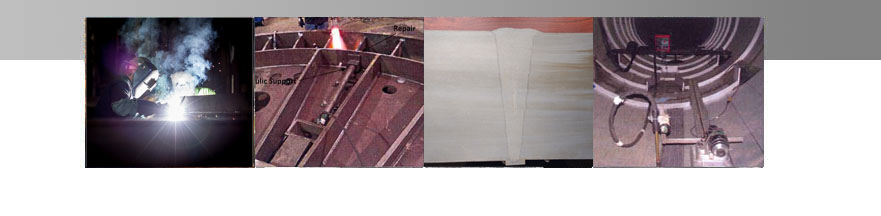

Weld troubleshooting / consulting services, providing repair solutions to manufacturing and field operating issues – keeping you compliant to ASME API, AWS and other relevant Engineering Codes.

Our services include weld testing, analysis and resolving weld (distortion / cracking /corrosion / fatigue / failure) issues – as well as joint analysis and stress analysis. Examples include:

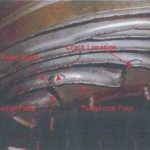

- Hydroelectric Shaft Exhibiting Flaws

- Cracked Tube-to-Tubesheet Welds on a Chemical Reactor

- Welding Procedures for P91 Heavy Wall Pipe

- Cracked 1,400 Ton Hydraulic Press

From Certified Weld Inspection Services (CWI) results, we provide engineering analysis and design weld repair solutions, often through the use of three-dimensional Finite Element Analysis (FEA).

Mechanical Engineering

- Weld Defects / Porosity

- Distortion / Cracking

- Weld Failures

- Fatigue Analysis of Welded Components

- PWHT / Heat Treatment Issues

- Weld Corrosion / SCC Issues

- Welding Metallurgy

- Weld Non-conformance

Weld Troubleshooting and Subsequent Redesign was performed on a heater that had a limited structural life. The heater was constructed of .025 inch thick stainless steel. The configuration includes an edge weld joint type, where two .025 sheets are placed side-by-side and the top surfaces are welded. When this is connected to the header, a three point T weld joint configuration is created. Many fatigue cracks initiated in this area.

To read more of our projects, see Portfolio.

Recent Projects

Engineering Support – Resolving Weld Issues

Durable welding is what holds every plant together. Often, equipment design life is compromised through inadequate manufacturing processes such as welding, thermal / transient conditions, and high temperature conditions. At elevated temperatures, creep, and component strains occur, especially in welded connections.

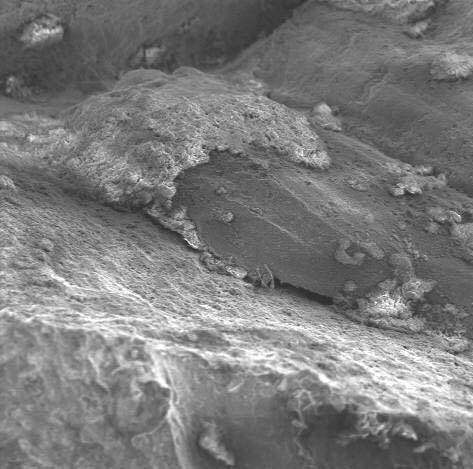

Defects often occur in welded, cast and forged parts. Parts with complex geometries often include crack starters such as metallurgical notch effects. Our services include Certified Weld Inspections (CWI) and Nondestructive Testing (NDT) – radiographic (RT) and ultrasonic (UT) to determine quality and serviceability. Read about the various types of NDT.

Often, local post-weld heat treatment (PWHT) operations are performed on welded assemblies and weld repairs to minimize weld residual stress and mitigate various damage mechanisms. Engineering support is required to minimize potential non-compliances.

We provide such support (including FEA) to optimize PWHT arrangements and thermal gradients to prevent detrimental distortion, cracking, excessive residual stress effects or fatigue failure.

Examples Include:

Experience

We are a team of multi-disciplined engineers providing clients with support across the spectrum of welding and joining challenges. This includes troubleshooting, code compliance, weld and joint inspection, mechanical testing, and evaluation of weld procedure specifications (WPS), procedure qualification records (PQR), and welder performance qualifications (WPQ).

Several of our senior engineers have developed patents, published technical reports, and have been active in Codes and Standards Committees including the American Society of Mechanical Engineers (ASME), the National Association for Corrosion Engineers (NACE), the American Nuclear Society (ANS) and the American Welding Society (AWS).

Call Tom O’Donnell to Discuss Your Welding Challenges.

Weld Consulting Related Links

>> Tom O’Donnell, PE

>> Materials / Metallurgical Consulting

>> Failure Analysis

>> Stress Corrosion Cracking Mitigation

>> Portfolio of Engineering/ Weld Projects

Learn from the experience of others. Especially when one such “other” is Dr. William O’Donnell, PhD, PE, Founder and President of O’Donnell Consulting Engineers, Inc., and ASME “Engineer of the Year” – his 50 years of experience in analysis of components including fatigue and fracture safety evaluations and failure analyses are now comprised in this volume.

If you are interested learning more in Engineering Design, Manufacturing and Construction, as well as Failure Analysis, then this book is a must have!

$49.95*

* Does not include shipping, handling or tax