Failure Analysis – Developing Expert Engineering Solutions

Failure analysis investigations and developing engineering solutions on equipment & structures to prevent recurrence. Our team of experts in engineering, metallurgy & welding investigate the root cause of structural failures due to thermal / transients, vibrations, thermal fatigue, etc., to ensure structural integrity, and maximize equipment reliability – ultimately controlling costs for owners/ users.

Applications include aluminum, stainless & alloy steels, titanium, and other materials used in industries including Aerospace, Petrochemical, Automotive, Medical, and Energy.

- Pressure Vessels, Piping, Valves, Pumps

- Tanks, Reactors, Dryers, Autoclaves

- Turbomachinery, Shafts, Blades, Gears, Bearings

- Heat Exchangers, Steam Generators, HRSGs

- Machinery, Lift Trucks, Cranes, Welded Structures

For a More Comprehensive List of Equipment, See Industries Served.

What We Do

Recent Projects

Although Many Components Break due to Fatigue Failure – Quite Often there are Additional Factors Involved – Including Coatings, Corrosion, Damage, Abuse, and Improper Manufacture. Contact Us to Learn More.

Recent Projects

Root Cause Failure Analysis

- Design Errors

- Material Imperfections

- Manufacturing Issues

- Weld Issues

- Improper Heat Treatments

- Fatigue / Fracture

- Misuse or Abuse

- Improper Maintenance

- Unforeseen Operating Conditions

- Inadequate Quality Assurance

- Environmental Issues (Vibration, Corrosion, etc.)

Interdisciplinary teams are essential for performing most failure analyses, since the root cause is rarely the result of a single variable. In performing metallurgical failure analysis, we investigate operational issues, environmental factors, load paths and stresses to a system or component.

Once we identify potential component failure modes, we design solutions & recommend inspection methods/ intervals to reduce the likelihood of future failures.

In elevated temperature applications, complicated failure modes may occur, such as creep ratcheting, rupture, and creep fatigue. Our engineers have the expertise, technology, and experience to identify and quantify these failure modes – helping you understand the root cause and developing solutions to prevent costly recurrences, thus improving safety and lowering operating costs.

Examples Include:

- Heat Exchangers

- Bellows

- Reactors

- Petrochemical

- Oil/ Gas

- Power Generation

- Refractory

- Ductwork

- Compressors

- Heaters

- Welded Assemblies

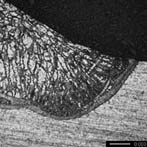

Metallurgical Testing

Failure analysis consulting requires metallurgical testing to evaluate the root cause of component failure, including corrosion investigations, surface condition studies, mechanical testing, and weld evaluations. This testing includes Chemical, Mechanical, Corrosion, Metallographic and Fractography (SEM & TEM).

Can’t find what you’re looking for? Try our Search Tool above.

If and when it becomes necessary to present the facts in court, we supply 3-D animations and multimedia presentations to accompany our expert testimony, clearly demonstrating the technical issues for Judges and Juries to easily understand.

To read more, see Expert Witness Services.

Give Us a Call to Discuss Your Engineering Challenges.

Failure Analysis Related Links:

>> Tom O’Donnell, PE

>> Materials / Metallurgical Consulting

>> Weld Troubleshooting / Consulting

>> Portfolio of Engineering & Legal Projects

Learn from the experience of others. Especially when one such “other” is Dr. William O’Donnell, PhD, PE, Founder and President of O’Donnell Consulting Engineers, Inc., and ASME “Engineer of the Year” – his 50 years of experience in analysis of components including fatigue and fracture safety evaluations and failure analyses are now comprised in this volume.

If you are interested learning more in Engineering Design, Manufacturing and Construction, as well as Failure Analysis, then this book is a must have!

$49.95*

* Does not include shipping, handling or tax