Engineering Design & Analysis

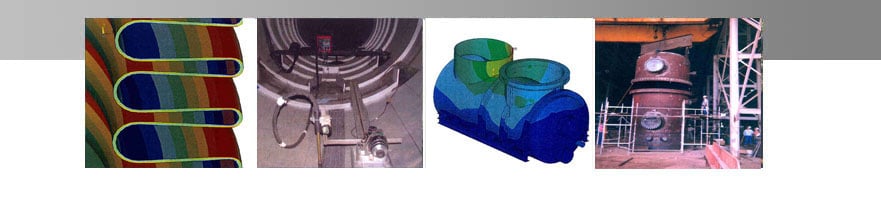

Engineering design and analysis (stress, thermal & fatigue) to codes including AWS, API and ASME (B&PV, Piping and BTH) – ensuring structural integrity of pressure & process equipment including pressure vessels, piping, and heat exchangers.

Whether it requires Closed-Form Design-By-Rule methods (ASME Section VIII Division 1) or Finite Element Analysis with Design-By-Analysis (ASME Section VIII Division 2) – we have extensive experience in design, analysis and optimization, maximizing equipment reliability and controlling costs for owner-users.

- Design and Analysis of Pressure Vessels and Process Equipment

- ASME B&PV Code Design and Analysis of Feedwater Heater

- ASME Power & Process Equipment (B31.1 & B31.3) Analysis

- Heat Transfer & Thermal / Transient Analysis of Equipment

- Optimal Design for Weight, Strength and Durability

- Stress & Seismic Analysis of Skids and Related Equipment

- Vibration and Fatigue Analysis of Components including Bellows

Mechanical Engineering

O’Donnell Consulting Engineers performed the design and analysis of elevated temperature / pressure vessels. One particular vessel had a specification to a no-leak condition. The challenge was to attach the hemispherical head to the shell without causing distortions, due to temperature differences. We thus designed a series of clamps to seal the two pieces together.

To see more of the projects we’ve worked on, see Portfolio.

Recent Projects

Engineering Design & Analysis Codes

- ASME Design & Analysis – Section VIII Div. 1, 2 and 3

- ASME Analysis – (B31.1 Power & B31.3 Process Piping)

- ASME Design & Analysis – (Below the Hook) BTH-1 & B30.20

- NBIC, API, ANSI, ASTM, AWS, MIL

- AISC, IBC, ISO, AWWA, AAR +

- International Codes including DIN, BSI

Additional Engineering Analysis Services

- Finite Element Analysis – reduces the time/effort/costs of physical testing

- Elevated Temperature Design & Analysis

- Design & Analysis of Perforated Plates

- Vibration/ Seismic Analysis – Response spectrum analysis and time history

- Linear and Non-Linear Large Deformation Dynamic Analysis

- Fracture Mechanics Analysis – In accordance with ASME Code Sections III and XI

- Fatigue Analysis – Fatigue is one of the most frequent causes of failure in pressure vessels, piping and process equipment. Vibrating components often lead to fatigue – and eventually to equipment malfunction, or catastrophic failure. Read the Blog on Pressure Vessel Design

Examples Include:

- Pressure Vessels

- Heat Exchangers

- Piping

- Skids

- Condensors

- Reactors

- Autoclaves

- Furnaces

- Cyclones

- Presses

- Conveyors

Learn from the experience of others. Especially when one such “other” is Dr. William O’Donnell, PhD, PE, Founder and President of O’Donnell Consulting Engineers, Inc., and ASME “Engineer of the Year” – his 50 years of experience in analysis of components including fatigue and fracture safety evaluations and failure analyses are now comprised in this volume.

If you are interested learning more in Engineering Design, Manufacturing and Construction, as well as Failure Analysis, then this book is a must have!

$49.95*

* Does not include shipping, handling or tax