Three-Dimensional FEA Analysis of VRU Base Skid

Structural & Modal finite element analysis (FEA) of a Vapor Recovery Unit (VRU) Base Skid was performed to ensure structural integrity to ASME Boiler & Pressure Vessel Code.

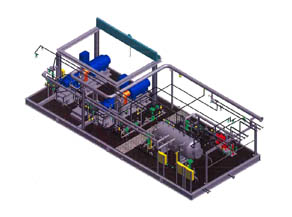

The skid package is used to recover process vapor for use as fuel gas – for a plant near Fort McMurray, North Alberta Canada. The equipment included motors, compressors, a separator, heat exchanger, instrumentation and controls, piping and valves, and miscellaneous components. The VRU base skid will also support the utility building in which the system will be located.

The combined VRU Base Skid and Utility Building structure is approximately 55 ft in length, 23 ft in width and 18 ft in height. The VRU Base Skid is a welded steel structure comprised primarily of American Standard W18x50 wide flange beams. The beams are mostly covered with 1/2-inch and ¾-inch thick steel partially connected (stitch welded in most locations) diamond plating. The diamond floor plates have not been designed to act compositely with the steel beams.

An overhead crane with associated support structure interfaces with transverse members of the base skid. The crane can access half of the overall skid, servicing the electric motors and compressors for the VRU system. Accommodation has been made for a transport vehicle such as a fork truck to enter the side of the utility building for retrieval and delivery of periodic maintenance components such as the motors and compressors. Design criteria for the base skid structure was obtained in part from the 2006 Alberta Building Code.

Three-dimensional structural analysis of the VRU base skid was completed for various individual and combined load cases. Resulting axial tensile and compressive forces and stresses, as well as bending stresses from these analyses were compared to corresponding allowable stresses according to the skid design criteria. The final design for the base skid was found to satisfy the specifications and design requirements.

A modal analysis was then performed on the base skid, excluding the piping spools and the building. The response of the skid in the region of the motor/compressor was investigated – in particular, the potential for the electric motor or compressors to excite natural frequencies in the skid structure. No excitable skid modes of vibration were found.

Piping analysis for the VRU Package was also performed, which included various thermal and structural load cases. The results determined that additional pipe supports were needed. The final design was within allowable stress criteria and satisfied the required specifications.

O’Donnell Consulting Engineers Performs Design & Analysis of Skids and Related Components to Codes including API, AWS and ASME

Related Projects

– ASME B31.3 Analysis of a Skid Mounted Heat Transfer System

– ASME B&PV Section VIII Div. 2 Code Analysis of a Feedwater Heater

– ASME Analysis of Offshore Skid

Similar Services

– Finite Element Analysis

– Engineering Design & Analysis

Resources

– Tom O’Donnell, PE

– Background of the ASME Code

– History of the ASME Code

– Portfolio: Finite Element Analysis Projects