Stress & Buckling FEA – Powder Decanter to ASME Section VIII Code

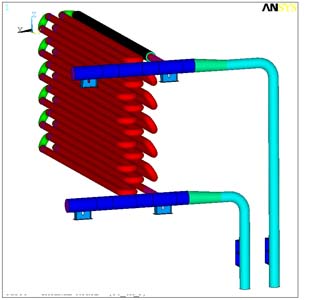

ASME Section VIII Division 1 (FEA) stress and buckling analysis on a decanter used to transfer microscopic materials.

Stress & Buckling FEA – Powder Decanter to ASME Section VIII Code Read More »