O’Donnell Consulting performed weld troubleshooting and subsequent redesign on a stainless steel heater exhibiting a limited fatigue life.

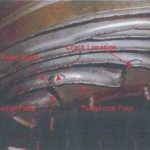

The heater was constructed of .025 inch thick stainless steel. The configuration includes an edge weld joint type, where two .025 sheets are placed side-by-side and the top surfaces are welded. When this is connected to the header, a three point T weld joint configuration is created by the intersection of the radial and tangential faces of the header and tube sheet. Many fatigue cracks initiated in this area.

Imperfections in fabrication processes such as welding, forming and assembling parts for welding and cutting can contribute to the concentration of strains in localized areas to a degree that significantly shortens the fatigue life of a fabricated unit. Sharp corners, large weld profiles, and undercutting also reduce fatigue life. After an examination of the fabricator’s process, we made design recommendations to reduce the likelihood of early fatigue failures.

We perform Weld Troubleshooting on vessels, heat exchangers, ductwork, heaters and other process equipment.

Related Projects

– Failure Analysis on Cracked Tube to Tubesheet Welds

– Assessment of Welding Procedures Used to Attach Appendages to P91 Heavy Wall Pipe

– Failure Analysis & Redesign of a Fracking Pump

Similar Services

– Engineering Troubleshooting

– Weld Consulting / Troubleshooting

– Manufacturing Consulting

Resources

– Tom O’Donnell, PE

– Publications: Pressure Vessels, Welds, Fatigue, Elevated Temperature