Chemical, Tensile and Hardness Tests were Performed along with SEM to Determine Cause

Engineering and metallurgical evaluations were performed on cracks that developed during qualification testing on an aluminum actuator arm of an aircraft landing gear.

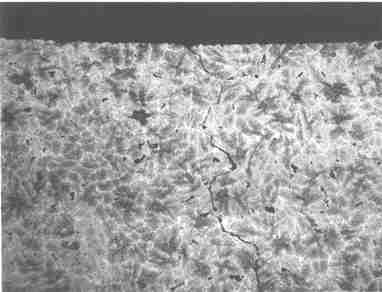

We performed chemical, tensile and hardness tests, along with visual and SEM examinations. The visual examination was performed at moderate magnifications using an optical stereomicroscope. On the outside diameter (OD) surface no cracks were observed in the marked and sanded area. On the inside diameter (ID) surface a small longitudinal crack was observed.

The surface of the tube in the marked area was further examined at higher magnifications using a scanning electron microscope (SEM) equipped with an energy dispersive x-ray spectrometer (EDS).

The scanning electron microscope revealed that the fracture had initiated at one location on the inside diameter surface. The longitudinal crack in the aluminum tube was found to actually consist of three separate cracks that had linked together and initiated on the inside diameter surface. The crack was found to be brittle in nature and no evidence of fatigue was observed. Pit-like flaws were observed on the ID surface of the tube that were found as deep as 0.0013 inches.

The pits may be sufficient to produce local cracking at the very low end of the fracture distribution curve. We recommended finite element analysis as well as fracture mechanics analysis to verify. By quantifying the size of the elongated pits which are significant to the cracking problem, the machining processes can be modified and/or heat treatment to eliminate the problem.

O’Donnell Consulting Performs Materials & Metallurgical Consulting – on Equipment for Clients in Industries Including Energy, Petrochemical and Aerospace.