A fire investigation was performed on a commercial grain dryer, which is used to dry soybeans.

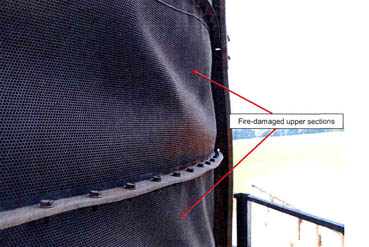

The dryer is a cylindrical, vertical, gravity fed, down flow type dryer with a diameter of 11’-8” and an overall height of 54’. The grain drying columns are 10” wide for the top 22% and 12” wide below. The cylindrical Grain Dryer resembles a donut in cross-section. The grain columns joined together form a ring located on the outmost portion of the tower. These columns are formed by perforated plates which direct the hot drying air across the falling soybeans (horizontally) and out through the tower exterior in the upper (heating) sections.

In the lower (cooling) sections of the grain columns, outside air is pulled through the soybeans into the center of the dryer. The air is thus preheated before entering the fans at the base of the tower and moving through the burner. This “suction cooling” feature reduces the energy consumption of the burner. The air is introduced at the bottom of the tower by two 30 HP double width / double inlet centrifugal fans. Thus, the air flows through a propane burner and vertically up the hollow interior of the tower.

We determined that origin of the fire was most likely in the upper section of the tower in one of the grain columns.

O’Donnell Consulting Performs Engineering Design & Analysis Services as well as Forensic Engineering Expert Witness Services.

Related Projects

– Propane Pump Explosion Investigation

– Investigation of Shipboard Compressor Fire

– Failure of XL Commercial Sprinkler Pipe

Similar Services

– Fire Explosion Investigations

– Murals of Projects

Resources

– Tom O’Donnell, PE

– Links to Engineering Resources

– Portfolio of Forensic Engineering / Expert Witness Projects