Brass Fittings were Evaluated For Stress Corrosion Cracking

Three leaded free machining yellow brass oxygen manifold fittings were evaluated for dimensions and evidence of stress corrosion cracking (SCC). The fittings were taken from service in an underground coal mine rescue chamber.

Visual evaluation indicated blue-green and red surface deposits, consistent with minor corrosion attack. Detailed metallographic evaluations confirmed the fitting dimensions were within the specified dimensional tolerances, and that the observed corrosion was confined to the surface. Brass materials containing greater than 15 wt % zinc are susceptible to dezincification and stress corrosion cracking (SCC), and should be replaced with red brass materials when possible in potential corrosion environments. Existing systems containing yellow brass components may be acceptable for use if stresses can be maintained below the threshold for SCC.

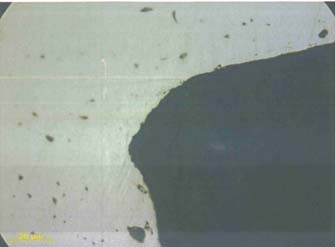

Close examination identified copper colored grains within the surface corrosion site. The presence of copper rich grains with corrosion products enriched in zinc are consistent with dezincification attack in yellow brass. All three fittings were evaluated metallographically for evidence of SCC. The figures shown here show high magnification as-polished and etched micrographs from the fitting inside corners showing no evidence of SCC. Only light surface dezincification attack was observed.

All three fittings exhibited dezincification attack confined to the surface, with chlorine identified as the aggressive species. No evidence of SCC was observed in any of the fittings. The presence of dezincification attack indicates the environment was sufficiently aggressive to also promote SCC in this alloy if sufficient stresses are present.

We Perform Metallurgical Analysis and Stress Corrosion Cracking Mitigation for Clients in Industries including Mining, Energy and Petrochemical.

Related Projects

– Failure Analysis of a Brass Fitting in a Chilled Water HVAC System

– Investigation of In-Service Cracking of a Lime Hydrator

– Analysis of Leaking Pump Seals

Similar Services

– Materials / Metallurgical Troubleshooting

– Engineering Troubleshooting

Resources

– Tom O’Donnell, PE

– Links to Engineering Resources

– Popular Links