Pressure Vessel Design and Analysis including Nozzles, (Saddle) Supports and other Appurtenances to the ASME Boiler & Pressure Vessel Code. Engineering includes stress, thermal, seismic/ vibration and fatigue analysis to Codes including AWS, API and ASME B&PV – ensuring vessel structural integrity.

We perform both closed-form Design-By-Formula Methods (ASME Section VIII Division 1) and Design-By-Analysis (ASME Section VIII Division 2) using Finite Element Analysis (FEA).

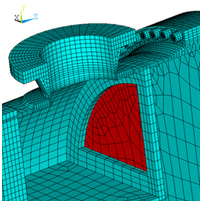

Pressure vessels have wide applications in power plants, as well as the process & chemical industries. Vessels often have openings of various diameters to accommodate manholes, handholds, and nozzles, that develop high stress concentrations which may lead to vessel failure. These geometric discontinuities alter the stress distribution in the neighborhood of discontinuity so that elementary stress equations no longer apply – and FEA is required.

Examples Include:

- FEA Pressure Vessel Design and Analysis to ASME B&PV Code

- Independent Design Reviews – Pressure Vessels, Nozzles & Supports

- Recertification Analysis of Aging Pressure Vessels

- Fatigue Analysis of Vessels used to Produce Hydrogen

- Design & Analysis of Pressure Vessels Operating at Elevated Temperature

Division 1 (Design by Formula) is a simple approach, using equations that produce a robust and proven conservative design. This approach works best on design of simple vessels, without any extreme geometric discontinuities (such as nozzles). For complex loads such as thermal shock or cyclic loading, FEA is used in accordance with Section VIII, Division 1, Mandatory Appendix 46.

Division 2 (Design by Analysis) is often performed using finite element analysis (FEA) to accurately predict stresses in complex vessels. FEA software is widely available its use is fairly common in engineering design. This method provides room for reducing weight while maintaining structural integrity.

Examples:

- ASME Pressure Vessels

- Accumulator Tanks

- Process Decanters

- Heat Exchangers

- Cryogenic Vacuum Chambers

- LNG Storage Tanks

- Liquid Oxygen (LOX) Tanks

- Liquid Nitrogen (LIN) Tanks

- Liquid Ammonia Tanks

- Chemical Reactors

Types of Engineering Analysis

- Stress Analysis

- Linear & Non-Linear

- Vibration & Fatigue

- Fitness for Service

- Fracture Analysis

- Design Optimization

- Fabrication Process Evaluation

- Heat Transfer

- Lifting Analysis

- Fatigue Analysis

- Thermal/Transient

- Flow Analysis

- Shock & Impact

- Safety Evaluations

- Elevated Temperature

- Structural Integrity

- Thermal Cycling

- Creep Fatigue

- Creep Ratcheting

- Buckling

Fatigue analysis is performed per ASME Section III Class 1 and Section VIII Division 2. The fatigue design life evaluation procedures in Section III of the ASME Boiler and Pressure Vessel Code were originally developed in the U.S. Naval Nuclear Program.

Those involved were Bill O’Donnell, (Bernie) Langer, W.E. (Bill) Cooper and James (Jim) Farr – who, in the late 1950’s and early 1960’s developed the initial formulation of this technology in the Tentative Structural Design Basis for Reactor Pressure Vessels and Directly Associated Components, which became known as “SDB-63.”

ASME Pressure Vessel Codes

- B&PV Section III Class 1, 2 and 3 Vessels and Components

- B&PV Section VIII Div. 1, 2 and 3 Vessels

- B&PV Sections IX and XI

Our Professional Engineers each have more than 30 years Experience – Multi-disciplined in areas of Design, Materials, Metallurgy & Manufacturing – and are Licensed in Numerous States.