Gouges in the Seal Surfaces were Responsible for the Leaks, along with Mineral Debris

Excessive wear and leaking on three nickel cemented tungsten carbide (WC) pump seals were investigated.

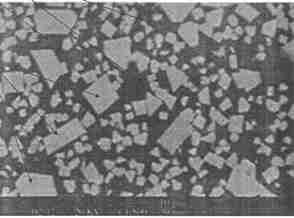

Visual examination revealed gouges in the seal surfaces that were responsible for the leaks, along with widespread mineral debris throughout. Analysis of the debris indicated that active corrosion was occurring in stainless steel, brass and aluminum components of the closed system. We also determined that elevated levels of aggressive fluoride salts suggesting untreated municipal water was used as makeup water.

Precipitation of abrasive silicon and aluminum oxides introduced fine abrasive particles into the system, preferentially abrading the soft nickel matrix of the cemented tungsten carbide pump seal, releasing tungsten carbide particles that further accelerated abrasive wear.

We recommended that the use of distilled or deionized water for makeup waters to eliminate concentration of water borne contaminants, and operating at pH levels between 8 and 8.5 to reduce attack of aluminum components.

O’Donnell Consulting Performs Analysis and Troubleshooting on Components for Clients in Industries including Energy, Manufacturing and Oil / Gas.

Related Projects

– Analysis of Replacement Reactor Coolant Pump Seals

– Fatigue Analysis on Threads of Base-Ported Pressure Filter

Similar Services

– Failure Analysis

– Materials & Metallurgical Consulting

Resources

– Tom O’Donnell, PE

– Popular Links

– Links to Engineering Resources

– Portfolio of Failure Analysis Projects