Failure & Metallurgical Analysis on Cracked Fittings

Failure and metallurgical analysis was performed on a commercial heating and air conditioning (HVAC) system that experienced cracks and leaking in brass valve fittings in a closed loop chilled (40 ºF) water system.

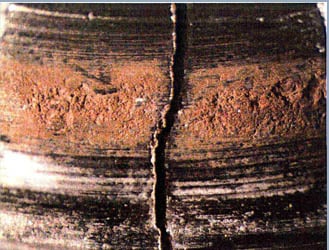

The fracture surface was examined at higher magnifications using a scanning electron microscope (SEM) equipped with an energy dispersive x-ray spectrometer (EDS). It was concluded that the fracture of the submitted brass connector initiated at a sharp corner on the inside diameter surface. Dezincification corrosion was found to be occurring at this location as well as other locations on the inside diameter surface. Dezincification is the selective leaching of zinc from brass alloys leaving behind a porous copper plug.

Based on the findings of the metallurgical investigation, it was concluded that the cause of the cracked and leaking valve fittings was dezincification corrosion caused by chlorine in the water system. The source of the chlorine was not identified. Possible sources include the city water supply or PVC or other polymers that may be part of the chilled water system. The removal of chlorine from the water or the use of dezincification resistant brass should prevent this problem from re-occurring in the future.

O’Donnell Consulting Performs Failure Analysis Services on Various Equipment including Fasteners, Valves and Fittings.