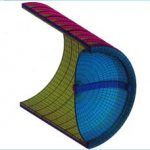

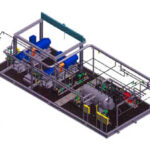

Performing finite element analysis (FEA) to Codes including API, AWS and ASME – ensuring equipment structural integrity, safety and reliability. These analyses include thermal/ transient, stress, vibration/shock and fatigue.

The benefits of FEA analysis are:

- Identifying equipment response to mechanical/ thermal loads to determine design/ material deficiencies – and designing subsequent improvements

- Quantifying design cycles, keeping production costs low through design optimization

- Uncovering potential sources of operational/field failures

- Improving operability and minimizing costs

We have supported clients in industries including Petrochemical, Mining, Manufacturing, Transportation, Aerospace and Energy.

Examples:

- Pressure Vessels

- Heat Exchangers

- Tumblers

- Piping

- Skids

- Compressors

- Pumps/Valves

- Cyclones

- Turbines/Shafts

- Assemblies

- Fittings

- Resistors

- Tooling

- Actuators

- Enclosures

Types of Analysis

- Stress Analysis

- Vibration & Fatigue

- Fitness for Service

- Fracture Analysis

- Design Optimization

- Fabrication Process Evaluation

- Heat Transfer

- Thermal Cycling

- Creep Ratcheting

- Linear/ Nonlinear

- Computational Fluid Mechanics

- Flow-Induced Vibrations

- Water Hammer

- Fluid Flow Analyses

- Thermal/Transient

- Shock & Impact

- Safety Evaluations

- Elevated Temperature

- Structural Integrity

ASME Codes

- B&PV Section III Class 1, 2 and 3 vessels and components

- B&PV Section VIII Div. 1, 2 and 3 vessels

- B&PV Sections IX and XI

- ASME B15, B16

- ASME B31.1, B31.3, +

- ASME Below the Hook BTH-1 & B30.20

Additionally, we have worked with Codes including API, ASTM and AWS. Finite element analysis requires a working knowledge of engineering mechanics and materials principles to get the answer right – the first time. Our professional engineers are licensed in numerous States – and multi-disciplined in areas of materials, design, metallurgy & manufacturing, each with more than 25 years of experience.